From inside (document excerpt):

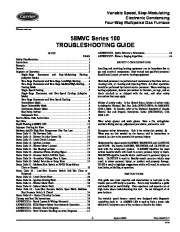

Variable Speed, Step-Modulating Electronic Condensing Four-Way Multipoise Gas Furnace Visit www.carrier.com 58MVC Series 100 TROUBLESHOOTING GUIDE INDEX PAGE Safety Considerations . 1 Instructions 1 Example 2 General 2 Sequence of Operation . 2 Single-Stage Thermostat and Step-Modulating Heating (Adaptive Mode) 2 Two-Stage Thermostat and Two-Stage Low/High Heating . 4 Two-Stage Thermostat and Two-Stage Medium/High Heating 4 Cooling Mode 5 Single-Speed Cooling 5 Single-Stage Thermostat and Two-Speed Cooling (Adaptive Mode) .

5 Two-Stage Thermostat and Two-Speed Cooling . 5 Thermidistat Mode . 6 Super-Dehumidify Mode . 6 Continuous-Blower Mode . 6 Heat Pump Defrost . 7 Component Test . 7 Service/Status Code Instructions . 8 Start Here 10 Rapid Flashing AMBER LED . 11 Improper Cooling Air Flow . 12 Medium And/Or High Heat Temperature Rise Too Low . 13 Status Code 11 – No Previous Code . 15 Status Code 12 – Blower On After Power Up . 15 Status Code 13 – Limit Circuit Lockout 16 Status Code 14 – Ignition Lockout . 17 Status Code 15 – Blower Motor Lockout . 17 Status Code 21 – Gas Heating Lockout 17 Status Code 22 – Abnormal Flame-Proving Signal . 18 Status Code 23 – Pressure Switch Did Not Open 18 Status Code 24 – Secondary Voltage Fuse Is Open . 19 Status Code 25 – Model Selection or Setup Error . 21 Status Code 31 – Medium-Heat Switch or HPSR Relay did not Close or Reopen . 22 Status Code 32 – Low-Heat Pressure Switch Did Not Close or Reopened 24 Status Code 33 – Limit Circuit Fault 26 Status Code 34 – Ignition-Proving Fault 28 Status Code 41 – Blower Motor Fault 30 Status Code 42 – Inducer Motor Fault . 32 Status Code 43 – Low-Heat Pressure Switch Open While MediumHeat Pressure Switch Is Closed . 34 Status Code 45 Control Circuitry Lockout . 34 Cleanup and Start-Up Instructions . 35 APPENDIX A – Board Layout & Wiring Schematic . 36 APPENDIX B – ECM Blower Motor Description & Operation 38 APPENDIX C – Pressure Check Diagram 40 APPENDIX D – Static Pressure Reading Location Diagrams 41 -1- APPENDIX E – Quick Reference Information .43 APPENDIX F – Furnace Staging Algorithm .44 SAFETY CONSIDERATIONS Installing and servicing heating equipment can be hazardous due to gas and electrical components. Only trained and qualified personnel should install, repair, or service heating equipment. Untrained personnel can perform basic maintenance functions such as cleaning coils, or cleaning and replacing filters. All other operations should be performed by trained service personnel. When working on heating equipment, observe precautions in literature, on tags, and on labels attached to or shipped with the unit, and other safety precautions that may apply. Follow all safety codes. In the United States, follow all safety codes including the National Fuel Gas Code (NFGC) NFPA 54-2006/ANSI Z223.1-2006. In Canada, refer to the National Standard of Canada Natural Gas and Propane Installation Codes (NSCNGPIC), CSA B149.1-05. Wear safety glasses and work gloves. Have a fire extinguisher available during start-up, adjustment procedures, and service calls. Recognize safety information. This is the safety-alert symbol

Carrier Owners Manual - 1 of 48

Carrier Owners Manual - 1 of 48 Carrier Owners Manual - 2 of 48

Carrier Owners Manual - 2 of 48 Carrier Owners Manual - 3 of 48

Carrier Owners Manual - 3 of 48 Carrier Owners Manual - 4 of 48

Carrier Owners Manual - 4 of 48 Carrier Owners Manual - 5 of 48

Carrier Owners Manual - 5 of 48 Carrier Owners Manual - 6 of 48

Carrier Owners Manual - 6 of 48 Carrier Owners Manual - 7 of 48

Carrier Owners Manual - 7 of 48 Carrier Owners Manual - 8 of 48

Carrier Owners Manual - 8 of 48 Carrier Owners Manual - 9 of 48

Carrier Owners Manual - 9 of 48 Carrier Owners Manual - 10 of 48

Carrier Owners Manual - 10 of 48