From inside (document excerpt):

Model No. 26 ” SNOW THROWER 314-830A For one year from date of purchase, MTD Products Inc., will replace for the original purchaser, free of charge, F.O.B. 1. Know the controls and how to stop quickly-READ THE OWNER’S MANUAL. factory or authorized service firm, any part or parts found to be defective in material or workmanship. All transportation 2. Disengage power and stop motor before cleaning discharge, removing obstacles, making adjustments, Or when leaving operation position. ; , charges on parts submitted for replacement under t1)is war· ranty must be paid by the purchaser.

Snow Blower and Snow Thrower User Manual Free Download. Snow Removal Operator’s Manual. Free Manual Download PDF.

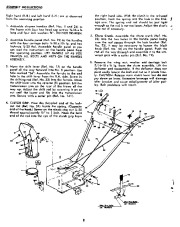

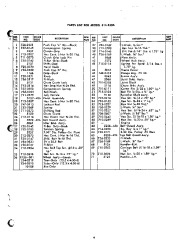

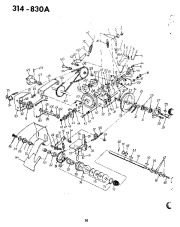

This warranty does not. 3. Never direct discharge at bystanders nor allow anyone in front of machine-debris may be hidden in the snow. 4. Keep children and pets a safe distance away. 5. Do not allow children to operate machine nor allow adults to operate it without proper instruction. include replacement of parts which become inoperative through misuse. excessive use. accident. neglect, improper maintenance or alterations by unauthorized persons. This warranty does not include the engine, motor, battery, bat· tery charger or any component parts thereof. For service on 6. Adjust height to clear gravel or crushed rock surface. 7. ,Exercise caution to avoid slipping or falling, especi when operating in reverse. these units refer to the applicable manufacturer’s warranty. The above warranty will apply only to the original owner and will be effective only if the warranty card has been properly processed. It will not apply where the unit has been B. Handle gasoline with care – it is highly flammable. A. Use approved gasoline container. B. Never add gasoline to a running motor – fill tank out of doors and wipe up spilled gasoline. C. Replace gasoline cap securely. D. Open door if motor is run in garage – exheust gases are dangerous. used commercially. Warranty service is available through your local author· ized service dealer or distributor. UNDER NO CI RCUM- ” · STANCES WILL THE RETURN OF A COMPLETE UNIT BE ACCEPTED BY THE FACTORY UNLESS PRIOR WRITTEN PERMISSION HAS BEEN EXTENDED. 9. Disengage all clutches and shift into neutnJ before staning motor. KllIlP hands, feet and clothing IIWrt from power driven I*1L 10. Use. grounded three wire exmnsion cord for ell plUll’ in electric units. 11. Keep machine in good operating -.dltion and keep $Ifety device in pl-. MTD “RODUCTS INC PRINTED IN U.S.A. · 5389 WEST 130th STREET · P. 0, BOX 2741 CLEVELAND OHIO 44111 FORM NO. 770·5524 ASSEMBLY INSTRUCTIONS Right hand (R.H,) and left hand (l.H.) are as observed from the operating position. the right hand side. With the clutch in the released position, hook the spring into the hole in the Iink- J .a age arm. The spring and rod should be just tight 1. Assemble chrome handles (Ref. Ncs. 8 and 24) to the frame with four hex head cap screws %-16 x enough so the rod is not too loose. Adjust the elastic stop nut if necessary. long and four lock washers “”’. DO NOT TIGHTEN. 2. Assemble handle panel (Ref. No. 29) to the handles with the four carriage bolts ;’·20 x 1].7 Ig. and hex locknuts ;’-20 thd. Assemble handle panel so you can read the instructions on the handle panel from ” the operating position. LIFT HANDLE UP AS YOU TIGHTEN ALL 80LTS AND NUTS ON THE HANDLE ASSEMBLY. 3. Move the shift lever (Ref. No. 17) on the handle panel all the way forward’into No.5 position: Use hole marked “26 “. Assemble the ferrule to the end hole in the shift lever from the R.H. side. Screw in the shifting rod (Ref. No. 32) into the ferrule. Move the shift lever into the reverse (R) position. Lift the transmission arm on the rear of the frame all the 5, Chute Crank. Assemble the chute crank (Ref. No. 33) into the two holes in the handle panel being sure the rod passes through the lock bracket (Ref. No. 23). It may be necessary to loosen the black knob (Ref. No. 18) on the handle panel. Push the rod all the way through and assemble it to the universai joint with a cotter pin (Ref. No. 71). 6. Remove the wing nut, washer and carriage bolt 5/16-18 x % Ig. from the chute assembly. Lift the deflector and reassemble. If the deflector does not pivot easily loosen the bolt and nut so it pivots free· Iy, CAUTION: Release main clutch lever but do not pry down on lever. Excessive leverage will damage idler bracket and cause misalignment of idler pul. ley. Belt problems will result. way up. Adjust the shift rod by screwing it on or out until the lower end fits into the transmission arm. Secure with a cotler pin (Ref. No. 141).

Wikipedia’s page for MTD Products

Publisher: www.mtdproducts.com

MTD 314-830A 26-Inch Snow Blower Owners Manual - 1 of 16

MTD 314-830A 26-Inch Snow Blower Owners Manual - 1 of 16 MTD 314-830A 26-Inch Snow Blower Owners Manual - 2 of 16

MTD 314-830A 26-Inch Snow Blower Owners Manual - 2 of 16 MTD 314-830A 26-Inch Snow Blower Owners Manual - 3 of 16

MTD 314-830A 26-Inch Snow Blower Owners Manual - 3 of 16 MTD 314-830A 26-Inch Snow Blower Owners Manual - 4 of 16

MTD 314-830A 26-Inch Snow Blower Owners Manual - 4 of 16 MTD 314-830A 26-Inch Snow Blower Owners Manual - 5 of 16

MTD 314-830A 26-Inch Snow Blower Owners Manual - 5 of 16 MTD 314-830A 26-Inch Snow Blower Owners Manual - 6 of 16

MTD 314-830A 26-Inch Snow Blower Owners Manual - 6 of 16 MTD 314-830A 26-Inch Snow Blower Owners Manual - 7 of 16

MTD 314-830A 26-Inch Snow Blower Owners Manual - 7 of 16 MTD 314-830A 26-Inch Snow Blower Owners Manual - 8 of 16

MTD 314-830A 26-Inch Snow Blower Owners Manual - 8 of 16 MTD 314-830A 26-Inch Snow Blower Owners Manual - 9 of 16

MTD 314-830A 26-Inch Snow Blower Owners Manual - 9 of 16 MTD 314-830A 26-Inch Snow Blower Owners Manual - 10 of 16

MTD 314-830A 26-Inch Snow Blower Owners Manual - 10 of 16